Description for 2019 SWDM360-H Rotary Drilling Rig

The SUNWARD SWDM360H rotary drilling rig, manufactured in 2019, is a powerful and efficient solution for heavy-duty foundation construction. With only 3,000 operating hours, it remains in excellent condition, offering both reliability and long service life. Equipped with a Cummins engine delivering 399 kW at 2100 rpm and a maximum torque of 360 kN·m, this rig combines raw power with fuel efficiency to handle the toughest drilling projects.

Built for demanding foundation work, the SWDM360H is reliable, strong, and highly efficient. It can drill to a maximum depth of 96 meters (optional 102 m) and achieve a maximum pile diameter of 2500 mm (up to 3000 mm with optional configuration), making it suitable for a wide range of piling applications such as bridges, high-rise buildings, subway construction, and energy infrastructure.

Beyond its core specifications, the SWDM360H offers several advantages:

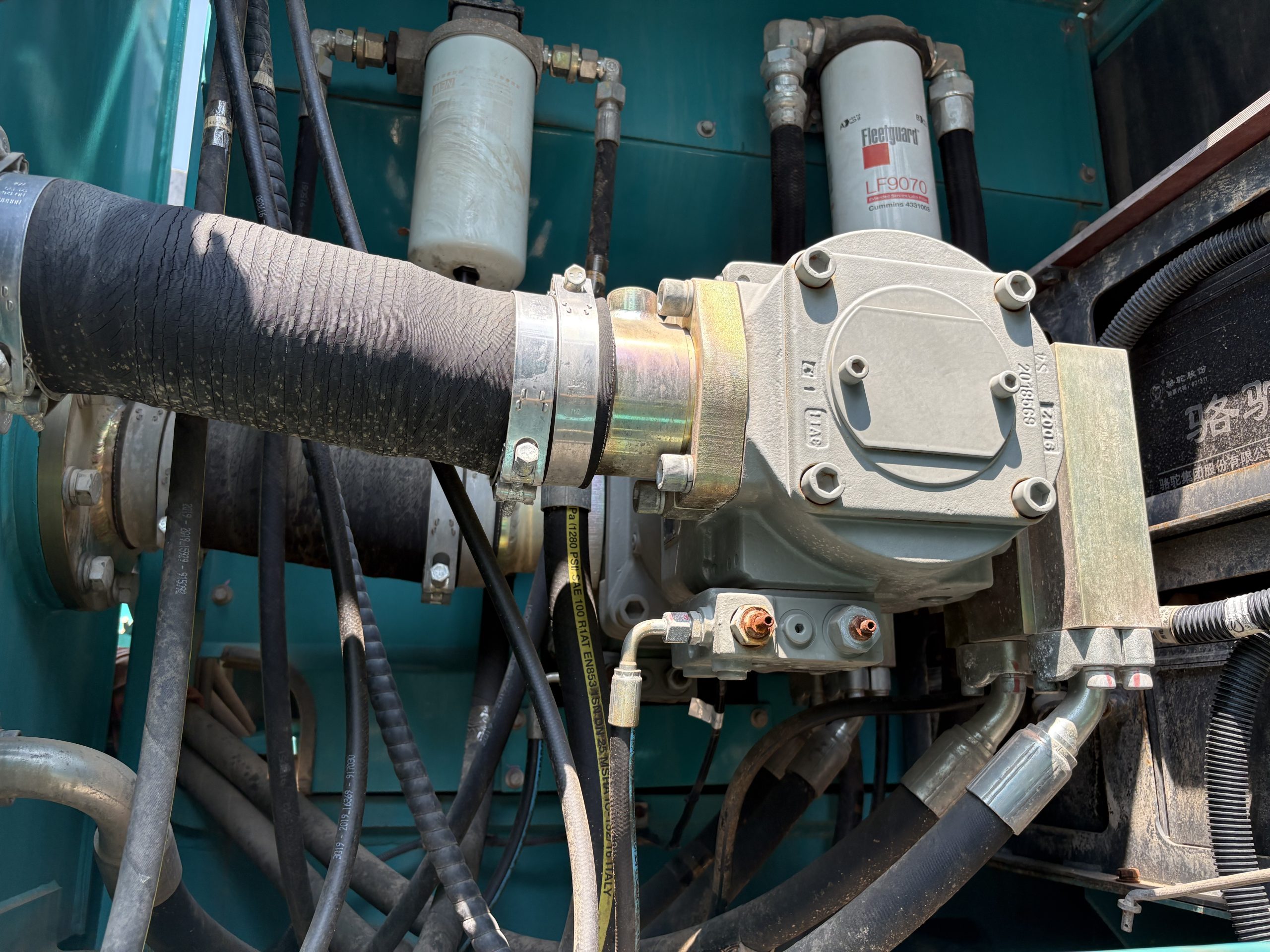

Advanced Hydraulic System – ensures stable, precise, and energy-efficient operation.

Robust Crowd Winch & CFA Options – improves versatility for different soil conditions and foundation techniques.

Heavy-Duty Mast & Structure – designed for durability and stability under high torque conditions.

Operator Comfort & Safety– spacious cabin with ergonomic controls, excellent visibility, and comprehensive monitoring systems for safe and efficient operation.

Easy Transport & Assembly – modular design allows for quicker mobilization and cost-effective transfers between job sites.

With its combination of high torque, impressive drilling depth, and flexible application capability, the SUNWARD SWDM360H is an excellent choice for contractors seeking a dependable and versatile rotary drilling rig ready to deliver performance on complex foundation projects.

WHY CHOOSE A USED CONSTRUCTION MACHINE?

Cost-Effective Without Compromising Quality

Used construction equipment typically costs 30%–70% less than new machines, giving you more value for your investment without sacrificing performance. The savings can be reinvested into other critical areas of your project or business.

Short Lead Time, Ready to Work

Skip the long factory production and delivery schedules. With used equipment, you get machines that are available immediately, helping you avoid costly delays and keep your projects on track.

Easy Access to Parts & Service

Most pre-owned models come with well-established service networks and readily available spare parts, ensuring quick maintenance and minimal downtime—no long waits for replacements.